Conversations with The Wood

Some people see wood as a dead thing, the last mortal remains of a long deceased tree. I’m not one of those people. I see a piece of wood and try and imagine the tree - sort of a fractal thing - the whole in each piece of the whole. And it’s not dead ‘cause it moves, which must be reckoned with if you’re going to make anything out of it.

And if you pay attention, and listen very carefully, IT TALKS.

Yup, it really talks. Not only that, but sometimes you can have quite a conversation with a piece. Some are quiet and not proned to conversation - probably from Connecticut trees.. Others are brash, perhaps from central Texas. The old growth stuff from the Northwest seem a little hard of hearing, take a little longer to respond, probably thinking things through first, but often come up with words of wisdom and sage advice. The wood from around The Great Lakes speak fondly andproudly of their ancestors while the wood from Pennsylvania and vicinity have a distinct German accent and speak in a very formal way. And there are subtle yet distinct accents in yellow pines, some have that Leon Russel pleasant southern drawl. But New York/ New Jersey woods (yes, there are trees there ) come with not only a distinct accent, but also an attitude - duh! The Canadian trees - well, you have to learn a little French if you’re going to understand them. After a while you stop noticing the accents and regional idioms and just hear what’s being said.

No doubt you’re saying to yourself - “This guys inhaled way too much sawdust. Wood talking? He needs to get out more.” Well read on my friend.

I’m building a cabinet maker’s work bench - you know, the L-shaped one with the shoulder vise. It’s semi-based on Frank Klausz’s bench in Scott Landis’s workbench book but with a Veritas Twin Screw end vise rather than the more traditional tail vise. This one’s gonna have a set of drawers under it and maybe some small tool storage on the ends.

Unlike most furniture, a real work bench is built with relatively massive components. Finding the stock of 8/4s, 12/4s and 16/4s in some of the widths required is not easy in a heavily urbanized area like Silly Cone Valley. But, in keeping with my philosophy that if you’re doing what you’re supposed to be doing things just serendipitously fall in place, they did.

I began the stock search at good old (and expensive) Southern Lumber. I started in the hardwoods area, wandering down the aisles, admiring the various woods but not finding anything thick enough for the legs. So off to the construction sized soft woods - to no avail. The size was available but the materials and grain were wrong.

Disappointed, I mosied towards the scrap/cut off bin in hopes of finding something interesting to make the trip worth it.

And on the way . . . the Sale Racks. Redwood, redwood, T&G cedar, oak 2x2s, pine 1x6s, pine 1x8s AND tight grained 3x4 pine! But pine? So, looking at the tops of the 3x4s I saw many were quarter sawn - hmmm. But pine? And the wood whispered “pssst - just pick me up and have a look.”

Pine? I don’t want no stinkin’ pine!

“Try us! “ the wood said a little louder., realizing that I hadn’t really heard it the first time.

“Pine?! You have to be kidding. Pine?”

“Just take me out of this bin and I’ll show you!”

So I did. Heavy for only three feet long. Almost straight grained quarter sawn and all heart wood. Put it on the floor and tapped the alternate corners then in the center to see if it rocked. Nope. Flip it over and repeat. Hmmm, flat Tried the the others combinations. They’re all nice and flat. Pulled out my square - hmmm- nice and square. This is interesting.

“You just might work.” I told the pine.

“Told ya’!” said the wood.

But finding seven 36 inches long and two 24 inches long took a while. Found all but one of the 3 footers. Well it was a long shot. I put all the wood back, explaining to the wood that they it wasn’t anything personal, just that there wasn’t enough of them. I was about to give up and try again later when I heard

“Man, you give up too easily. Look back here, under the stacked 20 inchers. Don’t know what the rack stacker was thinking when he stuck me back here with these little wimps.”

Took a while to find him - had to be a “him” with that attitude. “Where the hell are you you little ...” An inch longer than his 36 inch brethren he also was quarter sawn heart wood and hefty.

“I see you found them.” said the store manager. He’d apparently noticed me going through the racks, putting pieces on the floor and checking the corners with a square. I hoped he hadn’t listened in on my conversation with the wood because I don’t think he’d have heard the wood’s part of the dialogue. “I found this old stuff outback and had them mill it up, quarter sawn if they could. Figured someone could use it for a work bench or something. This stuff is getting harder and harder to find. What are you building?”

On the way home in the van we sang “It’s a Small World After All”

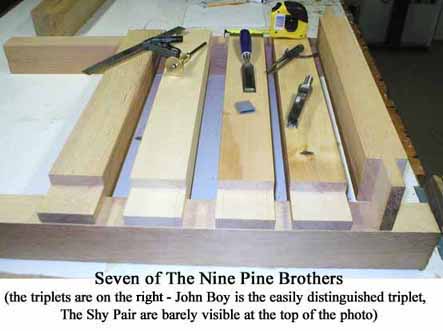

A week in their new home and it was time to start The Bench. With them layed out on the layout/assembly bench we started the “what should go where” process.

“We’re brothers - see how much alike we look?” said the triplets. So they became the three legs legs. A pair fought to see who’d have the upper and who’d get the lower ala kids and a bunk bed and that took care of one end of the bench’s base. The remaining two 3 footers just fell in place. That left the two footers. One was lighter than the other. “How do you guys feel about you being the base and you being the top?” “Seems fair to us, dark looks better closer to the ground anyway.” they said.

A little cutting here, a little trimming there, some mortise and tenons and viola - a good start on the base of the bench. Stood them up about how they’ll eventually be.

“Well watcha think guys?”

“All right!” they said in unison.

Then it was time for the stretchers.. I’m thinking ash. So off to Northern Hardwoods. The gate’s open, the warehouse door is open - but the lights are off. Mike comes out of the warehouse on a fork lift - “Sorry man but we’re closed.”

“Closed? On a Saturday at 10 am?”

“No man, we’re CLOSED. Done. Out of business. Finito. The owners packed it in.”

“Well can I at least wander around inside just for old time’s sake?”

“Sure, go ahead - but we’re closed.”

Most of the racks are empty, all the pallets of ply gone. Most of what’s left is knotty or twisted all to hell or full of checks and splits. With fallen shoulders I shuffled towards the door - sad and disappointed.

“What were you looking for?” Mike asks.

“I need some 8/4 ash or the like for a real workbench.” I said dejectedly.

“Well the only thing left that size is that spalted maple over there.”

Knowing the price of spalted maple and given the 8/4 thickness I knew they were out of the question being 8 1/2 - 10 inches wide and 10+ feet long I shuffled over “just to look”. One plank was quite handsome, nice distribution and pattern of the spalting and clean - no knot, no checks, no splits.

(here's The Tall Handsome One - turn your head to the left and you'll get the Tall part of his name . His top two feet are above the rafters. That's a four inch dust hose if you need some scale)

“Nice huh? I’d be great for your bench stretchers.” The Tall Handsome One said confidently.

The sign said Spalted Maple $14.95/BF. Quick calculation - Two times 10 times twelve divided by one forty four -

“Come on dude - you're close to twenty five bucks a foot! TWO HUNDRED AND FIFTY DOLLARS?!!!! -for a board?!!!!! This is going to be a freakin' work bench not the freakin’ Taj Mahal. Out of the question. Sorry.”

“Maybe he’ll make you a deal. At least ask him.”

“This sure is nice stuff but it’s just for a bench.” I holler to Mike.

“How about $3.50 a board foot?”

“DONE!” and I started to carry the tall handsome plank up to the counter.

That’s when the quiet one left in the rack spoke up.

“I know I’ve got some knots and splits and a check or two, but look more carefully. See the tiger grain up here and over there? Take me with you. Sixty bucks - what’ve you got to lose?

So I hauled Take Me Too up to the counter as well.

Then back in the back - some quarter sawn sycamore called me over. “Our cousins in your wood stash told us you liked quarter sawn sycamore. Well here we are!” the three 4/4 x 10” x 8 foot boards said in unison.

“But the sign says $10/BF! And I already have two long boards I haven’t figured out what to do with.” I said forcefully, seeing my checking account shrinking as we spoke.

“Don’t hurt to just ask right?” says the sycamore.

“Hey Mike, what about this sycamore?”

“How about $2.50 a board foot?”

Glee!

And as I was carrying the sycamore up to the counter another voice.

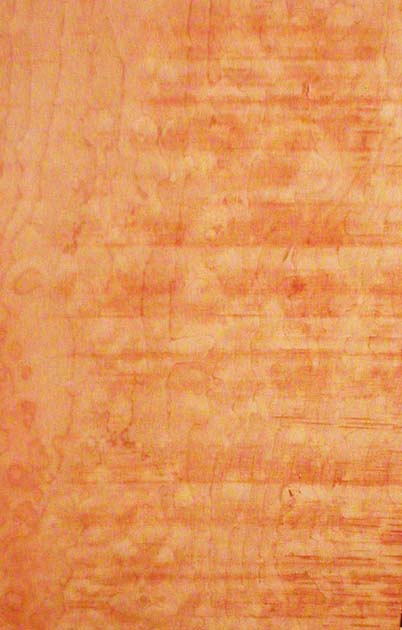

“Hey big boy - what da ya think of this?” said a brash Mae Westesque full figured quilted maple board that’d pop your eyes out.

“Sorry lady but you’re way out of my league.”

“You need a big beauty in your shop just to brighten things up a little - if ya know what I mean.”

(Mae - full frontal and a close up for Mr. De Mille)

“Is she, er, I mean is this piece of maple $3.50/BF too?”

“Sure.”

Wait, it gets even better. Since I was getting two of the spalted planks I got an even better deal - $75 bucks - for the pair! Kismet/kizmet (you get the idea)., fate, whatever you want to call it, these woods and I were meant for each other.

The Big Boys went on the roof rack and the rest were in the van in a flash. Mae sang on the way home. The sycamore probably blushed the whole way and the spalted maple on the roof rack surely did the dog with its head out the window grin thing during the ride to their new place.

Three or four days later it was stretcher time and another conversation with some wood - the Take Me Too spalted maple plank. Put him on the long miter saw tables, got out the tape, a pencil, a framing square and my bench drawings.

If only that knot weren’t there. Sure wish this cruddy area was a few inches that way. Why’d this soft spot have to be in the middle of this really nice area? Get one side working and find the other side had that darn knot.

I start looking towards The Tall Handsome One.

“Hey! Don’t give up on me! Get back over here!” Take Me Too insisted.

“Look, if you shorten these stretchers by an inch what’s it going to matter - this bad area is going to be gone when the tenon's cut right? And this section will work for the short stretchers on the ends and this nice spalted piece would be perfect for the spacer for the shoulder vise. I’ll tell you what to do with the rest later.”

So I looked and I measured. Take Me Too was absolutely right!

A little cutting to rough length, a little joining, planing and ripping and the four long and two short stretchers were ready to cut to actual lengths.

The 8 1/2 x 10 inch piece for the shoulder vise asked “Don’t you want to see just how nice I’m going to look in your new bench?” Got out the shellac and a piece of sweatshirt, donned some gloves and wiped on a coat or ten. I swear I heard the piece go “Ahhhhhh.”

“You can’t just shellac the top you know. I’ll cup if you don’t do the other side too.”

Now shellac dries fast so it wasn’t long before the 8 1/2 x 10 was nice an shiny - the grain popped and the spalting more pronounced. I stood it up near the end of the layout/assembly bench where it could watch without being in the way. “Thanks.” it said. “You’re welcome .” I replied.

(Here's The Spacer - nice huh?)

Cut the tenons on the long stretchers and did the layout for the mortises on the legs. Off to the mortising machine where I very carefully aligned the key faces of the chisel to my front and left layout lines. Maybe it was the motor’s noise or maybe the excitement of doing my second through mortise with this new mortising machine. I should have listened better because I know the wood was saying “You’re cutting on the wrong side of the layout line dummy!” I listened more carefully on all the rest of the mortises.

The through tenoned long stretchers came out nice and the wood kept saying “See? See! I told you I’d work. Don’t we all look nice together?”

“You’re right. I’m sorry I doubted you.”

(Here's some of Take Me Too as stretchers, stiles? and a munton/mutten? )

“Well please listen from now on. Now about the scraps you ripped off to get the stretchers ... We’re going to have drawers in here right? And you’e surely not going with a 30 inch drawer width so you’re going to need ...”

Up to now my conversations with the wood have been pretty rudimentary. It's going to be a while before I work up the courage to strike up a conversation with Mae. I'm going to have to become a much better wood workers before that happens.

I can’t even imagine the conversations James Krenov has with his wood or the dialogues that went on between George Nakashima and his wood. (Note - when I say "his wood" I don't mean "his possession" but more like "his friends".)

So - listen to the wood. Watcha got to lose?