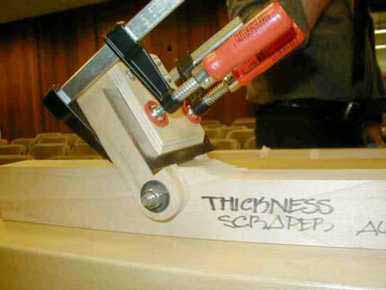

You've planed the stock close to the width you need. Now how do you take it down to what you need? Make another tool using a cabinet scraper of course. Here's The Thickness Scaper Mr. Fortune made and uses.

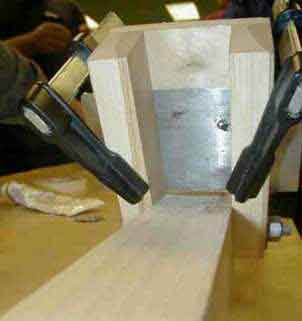

Here's the rear view. Stock goes in from the back and comes out thinner on the other side of the scraper. Scrape, test the fit and scrape some more 'til you get a good fit.

Here's more on The Thicknesser. The illustration talks about wire (you can also make line inlay from silver wire, left for another time) so substitute inlay wood in place of wire.

Once you've got your inlay groove cut and your inlay wood to the required thickness it's just a matter of cutting strips to length and a little wider than the groove is deep, a little glue, a little planing and sanding and you're done!

Michael Fortune is a very good teacher yes? I hope I'm a good student 'cause what you just went through is what I got out of his demonstration. If you find this information useful and/or inspiring you have Mr. Fortune to thank. Now go and do some line inlaying.