General 75-075 and PowerMatic 719A Mortising Machine Comparison

Let me preface this comparison by stating that I was in the market for a good power mortiser and, after a hands on comparison on the floor of a local tool supplier, selected the GeneralInternational 75-075.

The first thing to note is the price. The General is $800 US without a base unit while the PowerMatic is $800 US with the base unit. You can get the General base unit, but it's another $155 US. Both base units are too short for my liking, the table height being somewhere around waist high. I'm going to build a base cabinet for the General that'll put the table at 42 - 43 inches off the floor where I can see things clearly without bending over. Both units come with a 5/8 and 3/4 inch chisel collet - nice to have options and both come with 1/4, 3/8, 1/2 and 3/4 inch chisels and bits. The chisels and bits that came with the General will need a little clean up and polishing and I assume the same is true for the ones that come with the PM. From my experience with the JET chisels that came with my drill press, polished sides on the chisel will greatly reduce chisel stick.

Here are some side by side comparisons between The General 75-075 and The PowerMatic 719A mortising machines. The very significant difference between these machines is that the General 75-075 has a tilting head and horizontally pivoting fence.

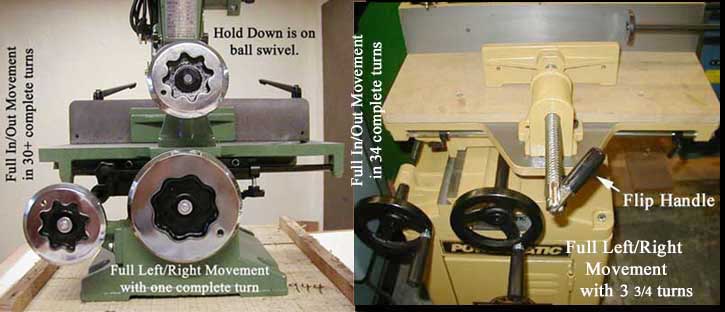

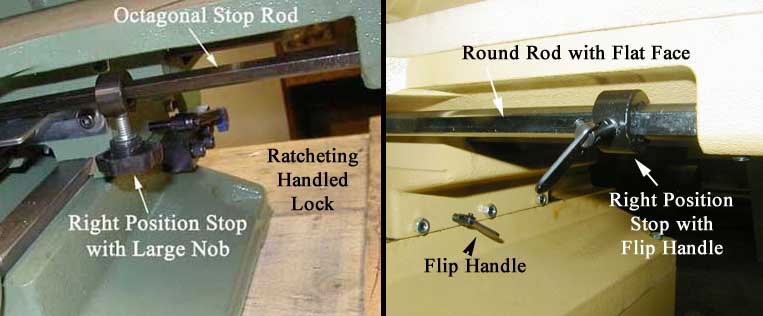

Here's a front view of both machines. Note that The General has wheels for the In/Out, Left/Right and Hold In while The PM has a "flip handle" for the Hold In. The flip handle on the PM appears awkward . However, a half turn counter clockwise releases the threaded shaft and this quick release then allows you to pull or push the hold in in or out quickly. A half turn clockwise re-engages the threads for tightening.

The lever arm bracket on The General is hexagonal and has three positions you can use for the lever arm with a ratcheting handled screw to lock the shaft in the bracket. The PM has only one lever arm mounting postion and an allen head set screw to hold the lever in.

Turns for Full In/Out Motion - General 38 PM 34

Turns for Full Left/Right Motion - General 1* PM 8

* General's wheel is almost twice the diameter of the PM so it's more equivalent to 2 turns on the PMNote the ratcheting handles behind The General fence. The fence pivots off the left side and ccan be rotated up to 30 degrees.

The image below shows the left side of each unit - both come with 5/8 and 3/4" chisel collets. Both units have a "return spring" (actually more like a gas shock). Both have setable depth stops but the General also has a "return stop" - handy given the lever arm length of both units

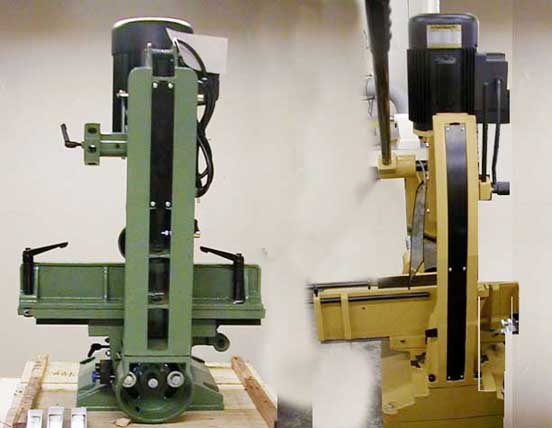

Here's the back of the units. The PM has a sheet metal shield covering the entire rear opening for accessing the pinion gear. The General cover is only over the area with the actual pinion gear. Might be an issue with cleaning out chips and sawdust. You can blow out the chips on The General but if they get into the lower area on The PM you might have to remove the cover to clean the area out. Probably a minor things but I'll mention it anyway.

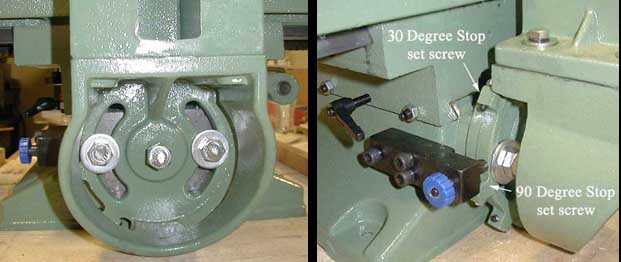

Note that the column on The General can rotate up to 30 degrees to the left or right of vertical while The PM column is fixed at 90 degrees. The General's column is more than twice as wide as The PM probably because of the tilt option. More on the head tilt feature late.

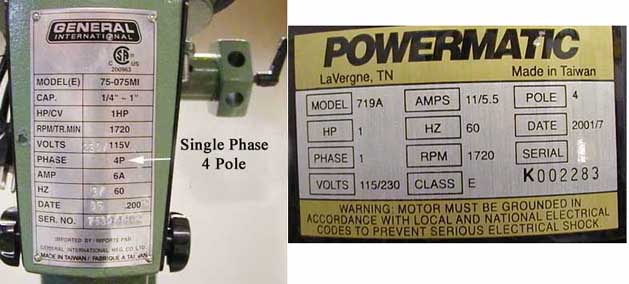

Here's the specs label for each unit. Both can be wired for 220V. These are both 1720 RPM motors, the lower speed supposedly reduces heat on the chisel and drill bit. Takes longer to make a cut but may extend the life of your chisels and bits.. Still not sure how 5.5 or 6 amps at 110V comes out to 1 horsepower (there are 745.7 watts/horsepower)

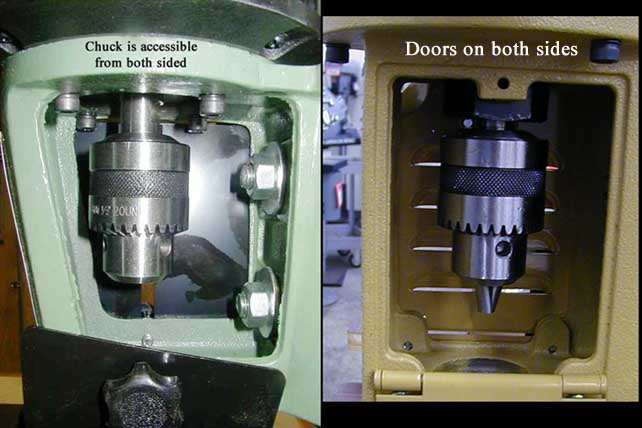

Both units come with a half inch drill chuck that appear to be MT2s (Morse Tapers) though, as noted by Dave Fleming, are probably Jacobs Tapers. The chuck is accessible from both sides on both units. The General has slotted drop down plates held in place with nobs. The PM has hinged doors which snap closed and also have screws to secure them - the screws will probably get lost after a short time.

The Left/Right Stops are, I feel, significantly different. The General has an octagonal shaft/rod while the PM has a round shaft/rod with one flat face on the front side. The hexagonal shaft lets you set the stop nob either facing foreward or down, a minor point. The difference in nob handle however is, I feel, significant. The PM flip handle is small and is hard on the finger and thumb when tightening. I don't know why PowerMatic went with so many little flip handles rather than round nobs or better yet, ratcheting handles. The PM flip handle for the in/out position lock is a real PITA while the General ratcheting handle is a relative joy. (see comments on the next image)

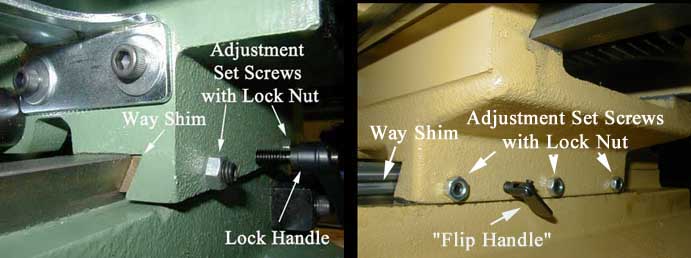

The image below shows details of the In/Out ways. It was the "way shims" and the little flip handle on the PM that got me leaning more towards the General. The shim on the PM a) is small with a V groove on its outside face and b) extends outside the casting. The PM floor model shim was also loose and when I tried to tighten the lock handle I found the flip handle set up a pain - literally.

On the other General, the way shim is taller and thicker AND there's a ratcheting handle on the lock mechanism which works a hell of a lot better than the PM flip handle set up.

Both units have depth of cut stops and return struts (real nice with motors this heavy). The General also has a "height stop" which prevents the motor from returing all the way to the top of its range of motion. A minor thing but nice if you're doing a lot of mortises. The PM has a nice big lever handle to set the depth stop while the General has smaller nobs. If the small nobs become a problem I'll replace them with ratcheting levers. Note that the General uses a stamped steel bracket for the stops. It should be OK but the PMs casting looks beefier.

Now to what really makes the General 75-075 different - the head tilt feature. The head can be tilted 30 degrees left or right of vertical! If you're doing chairs, anything with splayed legs or anything else that needs mortises that are not square to the face being mortised this feature will come in reall handy. Think of the possibilities1

Here's the back of the head tilt set up. Note the stops for +30, 90 - 30 degrees. The blue handled pin slips back to get to the -30 degrees side.

Finally, the fence can be pivoted on its left end up to 30 degrees. Not sure how useful this feature is but it's nice to have options.

Want to see a summary table of the key specs for these two mortisers? Then Click Here