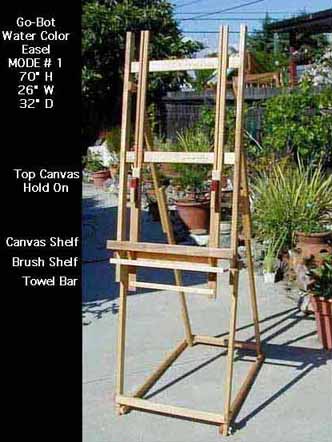

My adopted mom does water colors. I thought Id make her an easel. This started out as a simple ":A": with a third leg out the back. One carriage bolt, four 1x2s and two pieces of small chain, a couple of dowels and a screw or two.

Then I got the "customer's" requirements:

- fold up to fit under the bed or in the back of the closet

- light and easy to carry

- a place to hold brushes

- stand upright OR convert to a table when doing washes

So the "simple": easel turned into a folding Go-Bot with three modes - stand up tall easel, semi-sturdy four legged table and a 45":L x 25":W x 7:" D ":box":. It now has wedged through tenons, sliding dovetails, half lapped joints, dowels, dadoes and rabbets. There's pine, maple, elm, padouk, oak, some cherry ply and I think it may be hickory. The finish is primarily teak oil but there's also some tung oil and some water based poly on the wet brush shelf.

Started with the wedged through tenon "ladder", did a trial and error on the legs (a real hassle since things had to fold and fit inside of other things) and then the sliding dovetail system. The sliding dovetail parts with the pad/canvas shelf is a snug enough fit that it didn't require using the locking mechanism I';d worked out which involved an epoxied nut and a thunb screw coming into the female part of the dovetail from the back.

This was an interesting puzzle type project and quite different from making a cabinet, set of drawers or boxes. Plenty of winging it on this one.

Above images show the tablet / canvas ":hold on" which use a sliding dovetail to hold it on. They;'re maple, padouk and maple again. If I had it to do over again I'd probably skip the padouk since it is way too LOUD. This will be an easy modification since it's just a slide in part.

These pegs, connected to the easel by "tiger tail" wire, hold the legs in postion in the Table Mode. Attaching them to the easel with the tiger tail will, hopefully, keep them from getting lost.

Of course, this thing had to have a carrying handle. Had the maple so a little bandsawing and a lot of sanding, a couple of dowels, a dab of glue ...

Like the wall hanging tool cabinet, it was hard to say Basta! on this one. Kept finding ":just one more thing":

TIP: Drill a small hole at the bottom of each wedged tenon cut. Will keep the tenoned piece from splitting when you drive the wedges.(and it can split the wood if you hit the too firnly (Don't Ask Me How I Know).