CLOSE THIS WINDOW WHEN YOU'RE DONE WITH IT

Mitered corners look nice. But, without reinforcement, they're a weak End Grain to End Grain glue joint. Add some biscuits, a spline or some dowels and the joint becomes a lot stronger. BUT - if you're doing a 7 foot tall by 66 inch wide gate - well you're going to need a bit more reinforcement - say with four loose tenon mortise and tenon joints.

The problem is cutting mortises in end grain - on something SEVEN FEET LONG. Can't do end grain with a Chisel & Bit mortising machine. A router and a mortising jig can do end grain mortises - but not without a bit of a hassle when the mortises have to be in the end grain of something SEVEN FEET LONG! There is something called a horizontal boring/mortising machine that has an XYZ table to hold and position the part to e mortised - but the table isn't very big - and you've got something SEVEN FEET LONG to support - while allowing the part to move (the spiral bit that cuts the mortise is held fixed, the part must be moved to cut the mortise.

Now ALL of the above methods that CAN do the job require

a) a bit of mortise layout, either the ends and sides or the centerline/centerline and the ends

b) clamping the part to the device and setting up its position relative to the cutter along with

setting stops to limit the mortise length.

All that takes time - and a bit of precision - both in terms of layout and jig set up. Any error(s) WILL SHOW with mitered corners. The slightest misalignment will stand out like the proverbial Sore Thumb.

BUT - there is a way - and one that's quick, easy and accurate. Best of all it requires NO LAYOUT and practically no time for the Set Up. ( You're BSing me right? No layout lines AND essentially no set up? Seems I've heard THAT one before and 'tweren't so. So prove it!)

Another job for The DOMINO (Festool's that is)!

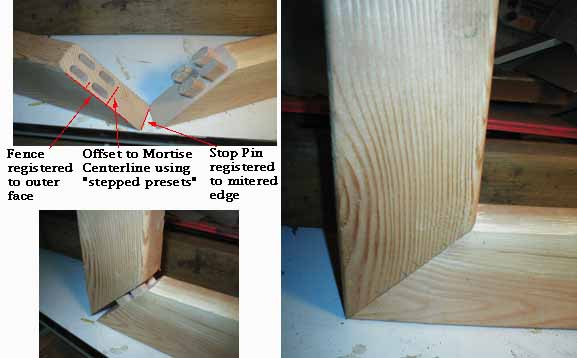

O.K. Here's the proof - four 10mm by 23mm by 25mm deep mortises (that's 0.393" by 0.906" by a tad less than 1" deep) - on each half of a 2x4 mitered corner. Two fence set ups for distance from fence to mortise centerline - using a "stepped presets" device on the DOMINO that works like the Depth Stop Turret on a plunge router. No eye balling the alignment of a reference arrow or reference line to a line on a scale. Figure out which "preset" will do what you need to do, select it, push the fence down against it - and GO!

But what about where the center of the long axis of the mortises will go?

No measuring or set up required. The DOMINO has a left and right retractable "stop pins" built into it's face - AND accessories "outriggers" with retractable "stop pins" that can be set anywhere from 100mm to 205mm from the mortise centerline. Reference a stop pin to an edge, in this case the knife edge of the mitered corner, and the center of the mortise will ALWAYS be 37mm from the mortise side of the "stop pin", or whatever distance you set on the outriggers, either the left one or the right one. Once the first mortise is cut you can reference the next one off either end of it using the 37mm retractable "stop pin".

How fast is it to cut four mortises in each end of a SEVEN FOOT LONG 2x4's mitered corners?

Under THREE MINUTE - and that's including clamping time, flipping the board around and reclamping. Did I mention that the person who cut all these mortises - HAD NEVER SEEN, OR USED A DOMINO BEFORE?

Couldn't glue this puppy up on my bench so it was done on my walkway/driveway - with wax paper under the corners to keep glue squeeze out off the concrete.

In case you're wondering why a 7 feet tall by 5 1/2 feet wide gate was needed - Doug made a nice BIG garden for his wife Sandy. Because their property is next to a creek (read deer and other wild life highway) he fenced the whole thing with 8 feet tall posts and "bird netting". To allow a truck or BobCat into the garden a wide gate was required. Here's one of the pair hung. A diagonal tension wire was added later

Yet another DOMINO application.

CLOSE THIS WINDOW WHEN YOU'RE DONE WITH IT